Share Post

ISO 45001 provides organisations with an effective framework to manage and improve safety, health, and wellbeing.

A well implemented system can also provide the organisation with many benefits including reputational, marketing, and financial benefits, improved efficiency, staff motivation and improvements to the supply chain by influencing supplier behaviour.

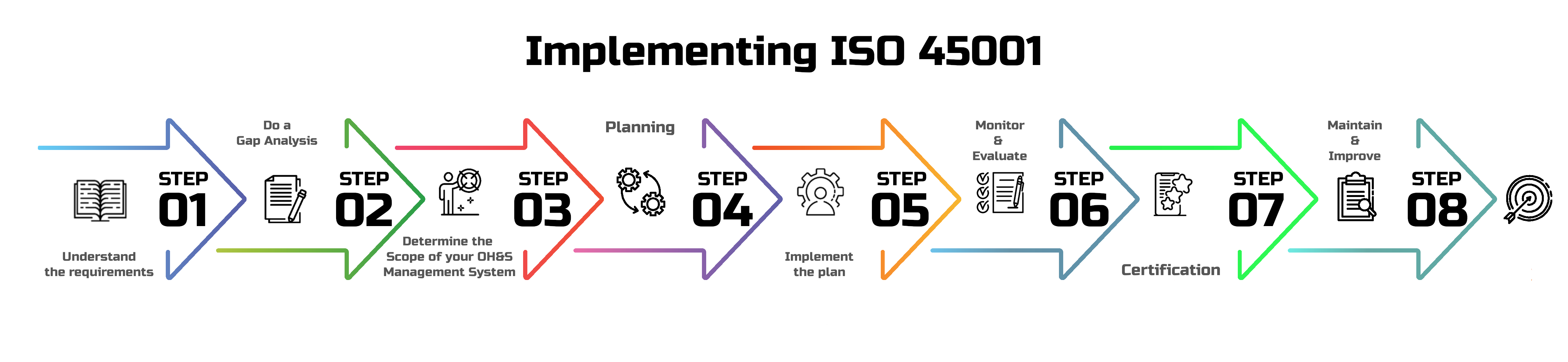

Sometimes the challenge is just knowing where to start. Below is a guide to implementing ISO 45001.

1. Understand the requirements

- Buy a copy of the standard

- Read about the requirements. There is a lot of free information available.

- Consider a foundation course on ISO 45001.

2. Carry out a Gap Analysis

- For each requirement see what is already in place and where you are not yet meeting the requirement

- Consider how you can use the current company’s resources, systems, and processes to integrate the safety system into your organisation.

3. Determine the Scope of your OH&S Management System

- Understand your strategic direction, activities, & boundaries of your organisation

- Determine internal and external factors that could impact on your safety management system

- Identify your interested parties and their requirements & expectations

- Document and define your scope

4. Planning

- Determine the process for consultation & participation

- Based on gaps and scope identify the processes that need to be controlled and create a plan

- Assign responsibility and timelines

- Set the OH&S objectives for the organisation and plan how these will be achieved

5. Implement the plan

- Implement the processes for control identified e.g. permit to work, emergency response etc

- Provide the training and information necessary

- Ensure all mandatory documented information is maintained

6. Monitor & Evaluate

- Set up internal audit programme

- Conduct a management review

- Identify monitoring required to ensure controls implemented are maintained and effective

7. Certification

- Stage 1 Audit – To assess that there is a system in place, documented information is available and there are processes in place to meet the requirements of the standard

- Stage 2 Audit – To determine controls are working as specified. An in depth look at the processes, records, activities, and behaviours.

8. Maintain & Improve

- Ongoing monitoring and evaluation of results to ensure the management system is working as intended and actions for improvement are identified.

- Identify nonconformities and take action to rectify. Identify and implement actions that will prevent recurrence.

- Identify and implement actions and changes that will further improve safety performance ensuring to include ongoing worker consultation & participation.

- Ensure documented information is maintained including review and update of risk assessments, objectives, legal requirements.